Specifications

Weight:

10,000 kg.

Height adjustment:

from 1300 to 1700 mm.

Feed speed:

0.082-0.102 m/sec.

Width:

2,800 mm.

Length:

14,300 mm.

Load capacity:

up to 40,000 kg.

Load force (nom.):

62 kN.

Electr. power:

19 * 22 kW + 2 kW.

Temperature mode:

from -20 to + 45 ° C; with heating from -30 °С

Weight:

from 18 000 to 20 000 kg.

Height adjustment:

from 1400 to 1800 mm.

Feed speed:

5 m/min.

Width:

2,350 mm.

Length:

14,500 mm.

Load capacity:

up to 40,000 kg.

Load force (nom.):

62 kN.

Electr. power:

26,75 kW + 2 kW.

Temperature mode:

from -20 to + 45 ° C; with heating from -30 °С

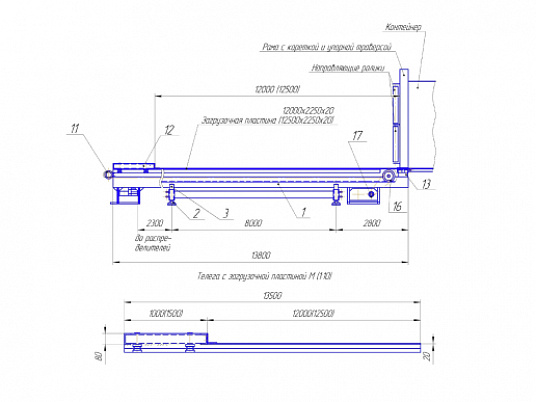

Weight:

12,000 kg.

Height adjustment:

from 1300 to 1700 mm.

Feed speed:

0,082 - 0,102 m/sec.

Width:

2,350 mm.

Length:

15,000 mm.

Load capacity:

up to 40 000 kg.

Load force (nom.):

62 kN.

Electr. power:

19*22 kW + 2 kW.

Temperature mode:

from -20 to + 45 ° C; with heating from -30 °С

Weight:

from 8000 to 10,000 kg.

Height adjustment:

from 1700 to 1900 mm.

Feed speed:

0,1 - 0,11 m/sec.

Weight:

2800 mm.

Length:

14,000 mm.

Load capacity:

up to 36 000 kg.

Load force (nom.):

50(5) kN.

Electr. power:

19*22 kW + 2 kW.

Temperature mode:

from -30°С to +45°С

Options

Device for loading pipes and logs of different diameters

Heating and cooling of oil in oil station

Frame with guide rollers at the container inlet

Remote control panel

Weighing device

Horizontal travel

Vertical travel

High shield pusher

Lighting masts

Oil level sensor

Heating and cooling of oil in oil station

Frame with guide rollers at the container inlet

Remote control panel

Weighing device

Horizontal travel

Vertical travel

Lighting masts

Oil level sensor

Device for loading pipes and logs of different diameters

Heating and cooling of oil in oil station

Frame with guide rollers at the container inlet

Remote control panel

Weighing device

Horizontal travel

Vertical travel

High shield pusher

Lighting masts

Oil level sensor

Device for loading pipes and logs of different diameters

Heating and cooling of oil in oil station

Frame with guide rollers at the container inlet

Remote control panel

Weighing device

Horizontal travel

Vertical travel

High shield pusher

Lighting masts

Oil level sensor

Principle of operation

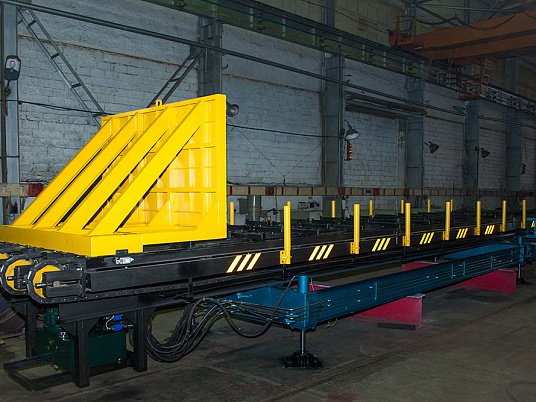

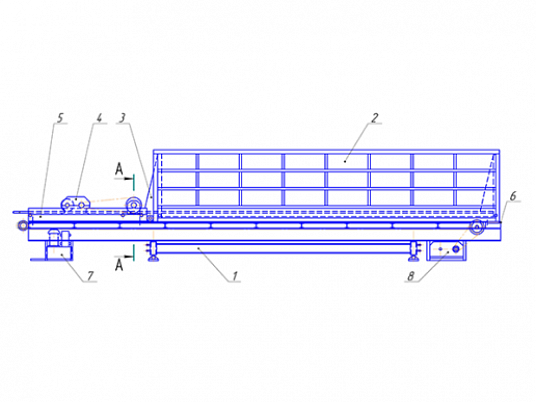

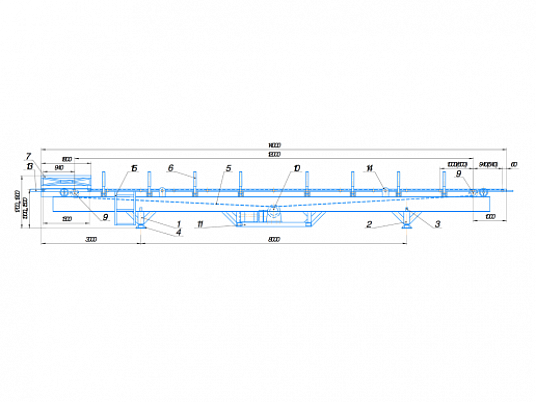

Container loading table (SPK)

The container loading table operates as follows:

- A vehicle with an installed empty container approaches the end of the platform. The worker, who controls the platform, adjusts it to the container floor level with the help of independently adjustable vertical and horizontal lifting hydraulic cylinders.

Container Loading Table (SPK UZK)

- По внешним боковым сторонам рамы на её поперечных балках смонтированы четыре гидроцилиндра для горизонтального перемещения платформы, которая закреплена на каретках сверху рамы. На платформе стола смонтирован четырех цепной поперечный транспортер. В конце платформы закреплена поперечная балка с механизмами гидравлической сцепки стола с корпусом контейнера.

Container Loading Table (SP2L)

Двухсторонний толкающий щит с приводом от реверсивной двухканатной

лебёдки обеспечивают двухстороннюю загрузку пакетов в контейнеры.

- К торцу платформы подъезжает транспортное средство с установленным на нём пустым контейнером. Рабочий, управляющий платформой, подстраивает её в один уровень с полом контейнера с помощью независимо регулирующих по всей высоте гидроцилиндров подъёма и гидроцилиндров горизонтального перемещения.

Key Benefits of Container Loading Tables

-

Temperature modeThey can be operated at temperatures ranging from -30 to +45 C.

Temperature modeThey can be operated at temperatures ranging from -30 to +45 C. -

Loading large volumesThey are suitable for loading 20, 40 and 45-foot containers

Loading large volumesThey are suitable for loading 20, 40 and 45-foot containers -

Easy to transportThe loading table can be easily placed on the truck loading platform

Easy to transportThe loading table can be easily placed on the truck loading platform -

Saving time and human resourcesLoading takes about 3 minutes and does not require a loader crew

Saving time and human resourcesLoading takes about 3 minutes and does not require a loader crew

Delivery of the loading table to any region of Russia

We work with all logistics companies. The loading table can be easily placed on the truck or wagon loading platform. Delivery takes at least 5 days. Request a call and we will calculate the cost and time of delivery to your region.

Request a callback

Who will benefit

-

Logistic centers

Logistic centers It is especially important due to the current deficit of gondola cars

It is especially important due to the current deficit of gondola cars -

Manufacturers of sawn timber

Manufacturers of sawn timber Saving time and working resources. Fast loading of sawn timber of various types

Saving time and working resources. Fast loading of sawn timber of various types -

Manufacturers of rolled metal products

Manufacturers of rolled metal products Optimization of the loading process for finished raw materials. High weight capacity

Optimization of the loading process for finished raw materials. High weight capacity -

Port organizations

Port organizations Work with large volumes of goods. Simple management of the loading table mechanism

Work with large volumes of goods. Simple management of the loading table mechanism

Review of the SPK table for loading sawn timber

Independently adjustable hydraulic lift cylinders

Independently working hydraulic cylinders moving load horizontally

Remote control of all mechanisms

Example of loading a container in 3 minutes

Container loading with sawn timber packages using the “SPK" loading table manufactured by LLC "Tyumen Machine-Tool Building Plant"

Request a consultation

Pricing factors

-

Specificity and working conditions of the products

Specificity and working conditions of the products -

Technological loading scheme

Technological loading scheme -

Loading area dimensions

Loading area dimensions -

Loading equipment, availability of railways and highways

Loading equipment, availability of railways and highways

Customer testimonials

Лесозавод "Судома"

We operate the loading non-stop (if there are no container loading operations, we put it in the idle cycle twice a week).

The table works without any problems; there have been no failures. In cold weather, down at -20 C, it also worked fine (we have not experienced lower temperatures yet).

As for wishes, it would be good to design a different weighing mechanism, because the load sensors went out of order and need to be checked.

Bayandin Konstantin Andreevich

Development Director

ООО "Орион"

The table corresponds to the price-quality combination. It is a good alternative to the expensive imported devices.

Dmitriy Uryevich Rybin

Commercial Director

ООО "СиблесПроект"

The installed equipment, loading table SPK-00.00.000 factory No. 17, located at: Krasnoyarsk Territory, Enisey District, Vernepashino settlement, Soviet str., 1b, has been in industrial operation since October 23, 2017. During this time, the equipment performed really well. It is reliable in operation and has minimal service and maintenance costs. The declared technical characteristics of the equipment correspond to the real ones.

Е.А. Kulagin

Chief Engineer

АО "Югорский Лесопромышленный холдинг"

После года использования, оценив преимущества данной конструкции в простоте

эксплуатации, а также в связи с увеличением объёмов отгрузки появилась потребность

в закупке ещё одной установки для загрузки контейнеров и летом 2017г. мы приобрели

второй стол перегрузочный СПК, нареканий к работе в условиях крайнего севера этого

оборудования нет, загрузка контейнеров осуществляется регулярно без задержки. Цена

значительно ниже импортных аналогов таких устройств, качество конструкции нс уступает

существующим аналогам.

E.B. Panushkin

Leading Specialist

Our advantages

-

In-House ProductionAll the development of the device takes place at our plant

In-House ProductionAll the development of the device takes place at our plant -

Extensive ExperienceWe are the first manufacturer of loading tables in the CIS countries

Extensive ExperienceWe are the first manufacturer of loading tables in the CIS countries -

Warranty 12 monthsWe provide maintenance service

Warranty 12 monthsWe provide maintenance service -

High demandWe sold 17 units in Russia and abroad

High demandWe sold 17 units in Russia and abroad